With excellence in boiler manufacturing, NG is active in the FOOD and VEGETABLE OIL markets, serving the main industries in these sectors.

NG has an engineering team with broad experience in mechanical projects, meets the strictest demands of quality and main project and manufacturing standards, using the latest generation equipment and a highly trained team.

NG is outstanding for manufacturing equipment with a wide variety of materials, within the most varied standards, and applying the most diverse welding processes, such as:

1. FABRICATION MATERIALS

- Carbon steel A36, A-283-C, A-285-C, A-516-60/70, A-572-50

- Stainless steel 304, 304-L, 316, 316 l, 317 L, 904 L

- Duplex UNS31803 /32205

2. Project and Manufacturing Standards

- ASME Seção VIII Div.1-TEMA-API 650 and 620

- AISC NR 13-NBR-06123 and 07821

3. Welding Processes

- In accordance with ASME Section IX and AWS standards

- Processes FCAW-SAW-GTAW-GMAW

- Qualified Inspectors: SNQC-FBTS-ASNT-ABENDE

With a view to maintaining quality and complying with their customers’ standards, NG has various certifications, such as:

- ISO 9001

- DNV

- ASME “U” STAMP

- CRCC PETROBRAS.

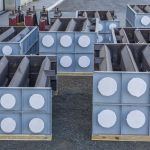

Among the innumerable items manufactured in this market, the following items of equipment are outstanding:

- Storage tanks made of carbon steel and stainless steel

- Pressure vessels made of carbon steel and stainless steel

- Evaporators made of carbon steel and stainless steel

- Heat exchangers made of carbon steel and stainless steel

- Fermenters made of stainless steel.

- Reactors made of carbon steel and stainless steel with internal polishing

- Condensers made of carbon steel and stainless steel

- Cyclones made of carbon steel and stainless steel

- Aspirators made of carbon steel and stainless steel

- Process towers made of carbon steel and stainless steel

- Fermenters made of carbon steel and stainless steel

NG has a differential in meeting the demands that require erection directly at the customer’s site, using their own teams or outsourced teams under supervision.